We Know Water

We Know Water

Cafe

Aqualife’s reverse osmosis system offers a range of built-in re-mineralisation filters to provide the highest quality water needed

Food Services

Medical

+ Dental

Reverse osmosis and deioniser filter systems produce the purity of water needed for medical, veterinarian and dental applications

Office +

Home

The quality of drinking water across the globe varies according to each region, infrastructure and the geological nature of the terrain.

Water Innovation

At Aqualife, our focus is always on the careful management of our precious resource — water. In order to achieve the best results, our company is constantly investing in innovation and exploring new technologies to present the most efficient and cost-effective water treatment products.

Regardless of whether it is used for drinking, keeping our trains running, enjoying your morning coffee or keeping our medical and dental surgeries operational, it is our duty and privilege to make a significant contribution to the economic activity of Australia’s vibrant, technically driven society.

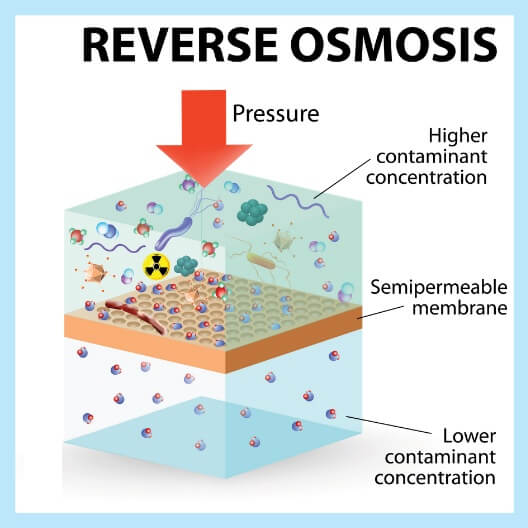

Reverse Osmosis Technology

Reverse osmosis is a water purification process that is also referred to as desalination. Unwanted dissolved mineral and salt molecules and larger particles are removed from tap water by using a partially permeable membrane. In reverse osmosis, an applied pressure is used to overcome the natural osmotic pressure. Reverse osmosis can remove many types of dissolved minerals and salts, suspended solids as well as endotoxins.

Reverse osmosis technology is used in both industrial processes and the production of potable water — which is water safe enough to drink. Reverse osmosis is a proven cost-effective and secure technology to combat water quality issues. In comparison, the life of resin in water filtration processes is governed by the level of salts in the feed water. Whereas, in reverse osmosis technology the system prohibits the movement of unwanted molecules to pass through the fabric of the membrane.

Innovation is our strength

Carbon

Aqualife uses two forms of carbon: Granular activated carbon

(GAC) and CTO carbon block.

Since Aqualife’s inception, we have been particular in our selection of GAC filter components because of the huge variation available in

carbon specifications.

Aqualife specifies the exact raw materials used in the production of our GAC cartridges, which ensures best practice in manufacturing.

Because of this attention to detail, our customers can be

assured of the high performing absorption properties of Aqualife’s carbon-based cartridges. This is important in the pre-treatment process in reverse osmosis, or where adverse taste will impact on the quality of the finished product — in a cafe, for instance.

All carbon used by Aqualife is selected on the following characteristics.

- Apparent density

- Particle size distribution

- Hardness

- Total Ash Content

- pH

Aqualife also offers specialty reverse osmosis systems to achieve great results in the reduction of total dissolved solids (TDS) including excessive chlorides content.

Aqualife is continually innovating through ongoing internal R&D programs. At Aqualife, we believe in striving to transition new and existing technologies into ground-breaking products for all our customers.

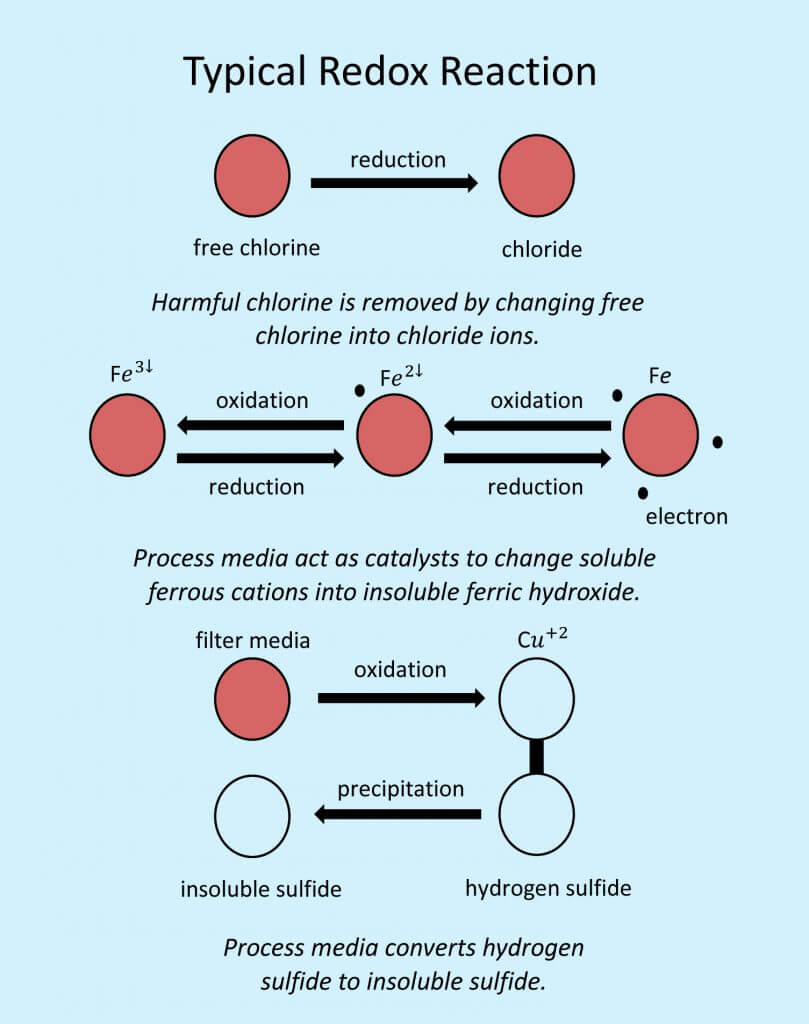

Aqualife & Redox Technology

Aqualife has used redox technology, also known as the oxidation reduction process, for over 25 years.

This bi-metal technology of copper and zinc creates an electro-chemical reaction, during which electrons are transferred between molecules, new elements are created, and some harmful contaminants become benign. Similarly, heavy metals including copper, lead and mercury react to plate out onto the medium’s surface, thus being effectively removed from the water supply. This means a reduction in limescale accumulation which can be so harmful for machinery. Furthermore, this material will also use less acid in the descaling process creating an improved occupational health and safety work environment.

The process componentry is micro bacteria static and therefore helps to create a safe working environment and a healthier drinking beverage.

The componentry is also 100% recyclable.

Aqualife Quattro Technology

Quattro technology is specifically chemically engineered for the coffee, food and beverage industries. The Aqualife Quattro cartridge incorporates redox copper zinc technology. This cartridge design maximises contact time with unfiltered water and provides a comprehensive five-stage water treatment system. This has very positive benefits, including:

- A reduction in suspended solids such as dirt, rust sand and mud.

- The removal of 85% of free chlorine.

- Reduction of heavy metals contamination, in particular iron.

- Creates a safe micro bacteria environment free from silver impregnated carbon.

- The large surface area from specially selected granular activated carbon results in a high level of organic chemical and free-chlorine removal.